Coconut trees are one of the most versatile plants in the world, with nearly every part of the tree being used for various purposes. The outer layer of the coconut fruit, known as the coconut covering, is no exception. Coconut covering has been used for centuries for many applications, from producing fuel and charcoal to making handicrafts and serving as a growing medium for horticulture.

Contents

What is The “Coconut Covering”?

Coconut covering refers to the outer shell surrounding a coconut fruit. The shell is typically hard and fibrous, with a brown or tan colour. It protects the coconut fruit inside and can be used for various purposes, such as making handicrafts, fuel, and charcoal.

The fibres from the coconut covering, known as coir, are also commonly used in making products such as mats, ropes, and brushes. You can use the coconut covering in cooking as a vessel for serving food or as a natural bowl.

Using coconut covering in various applications has many environmental benefits, including reducing waste and providing a sustainable alternative to non-renewable resources. The importance of coconut covering has proven to be a valuable resource for many industries while contributing to sustainability efforts.

Physical Properties of Coconut Covering

Description of coconut husk

The coconut husk is the hard outer layer of the coconut fruit that protects the inner flesh and liquid. It comprises three layers: the exocarp, mesocarp, and endocarp. The exocarp is the smooth, outermost layer, green when the coconut is young and turns brown as it matures. The mesocarp is the fibrous middle layer that surrounds the hard endocarp. The endocarp is the thickest and hardest layer containing coconut meat and water.

The coconut shell husk is typically oval-shaped and is about 10 to 12 inches long and 7 to 8 inches in diameter. The shell’s texture is rough and fibrous, and it is usually a light brown or tan colour. The shell is tough and durable, making it ideal for various applications such as handicrafts, fuel, and charcoal production. Additionally, the fibres from the coconut shell, known as coir, are commonly used in horticulture and other industries.

Chemical composition

The chemical composition of the coconut covering varies depending on their maturity, location, and other environmental factors. Generally, the shell comprises cellulose, lignin, hemicellulose, and other minor components such as ash, protein, and lipids.

Cellulose is the main structural component of the coconut shell, making up about 35-40% of its weight. Lignin is another important structural component that provides the shell with its hardness and durability. Hemicellulose is a complex polysaccharide that contributes to the shell’s structural integrity.

Ash content in coconut shells is typically between 0.6% to 4%, mainly calcium, potassium, and magnesium. Proteins in the shell are present in low amounts, with a range of 0.2-1.8%. Finally, the lipid content in coconut shells is relatively low, at around 3-5%.

The chemical composition of coconut shells makes them ideal for various applications, such as producing activated carbon, charcoal, and other industrial products. Additionally, the coir fibres derived from the shells have excellent water-holding capacity, making them useful in horticulture and soil stabilization.

Color, texture, and hardness

Coconut covering, which refers to the outer layer of the coconut fruit, has distinctive color, texture, and hardness characteristics that make it a versatile material for various applications.

The color of the coconut covering varies from light green to brown, depending on the maturity of the fruit. When the fruit is young, the shell is green, and it turns brown as it matures. The color of the covering has no significant impact on its physical properties and is usually used for aesthetic purposes in handicrafts and decorative items.

The texture of the coconut covering is fibrous and rough. The fibres are dense and tightly packed, giving the covering a rigid and sturdy feel. The texture of the covering makes it ideal for producing handicrafts, garden mulch, and other materials that require a tough and durable material.

The hardness of coconut covering is another important physical property that makes it useful in various applications. The shell is hard and sturdy, providing excellent protection to the inner fruit. This hardness makes it ideal for producing handicrafts, fuel, and charcoal. Moreover, the fibres from the covering, known as coir, have excellent water retention properties, making them suitable for horticulture and soil stabilization.

In summary, the color, texture, and hardness of coconut covering make it a versatile material for many applications, from producing fuel and charcoal to making handicrafts and serving as a growing medium for horticulture. The covering’s unique physical properties contribute to its sustainability and make it a valuable resource in various industries.

Applications of coconut covering

Coconut covering, the outer layer of the coconut fruit, has several applications due to its unique properties. Here are some of the most common applications:

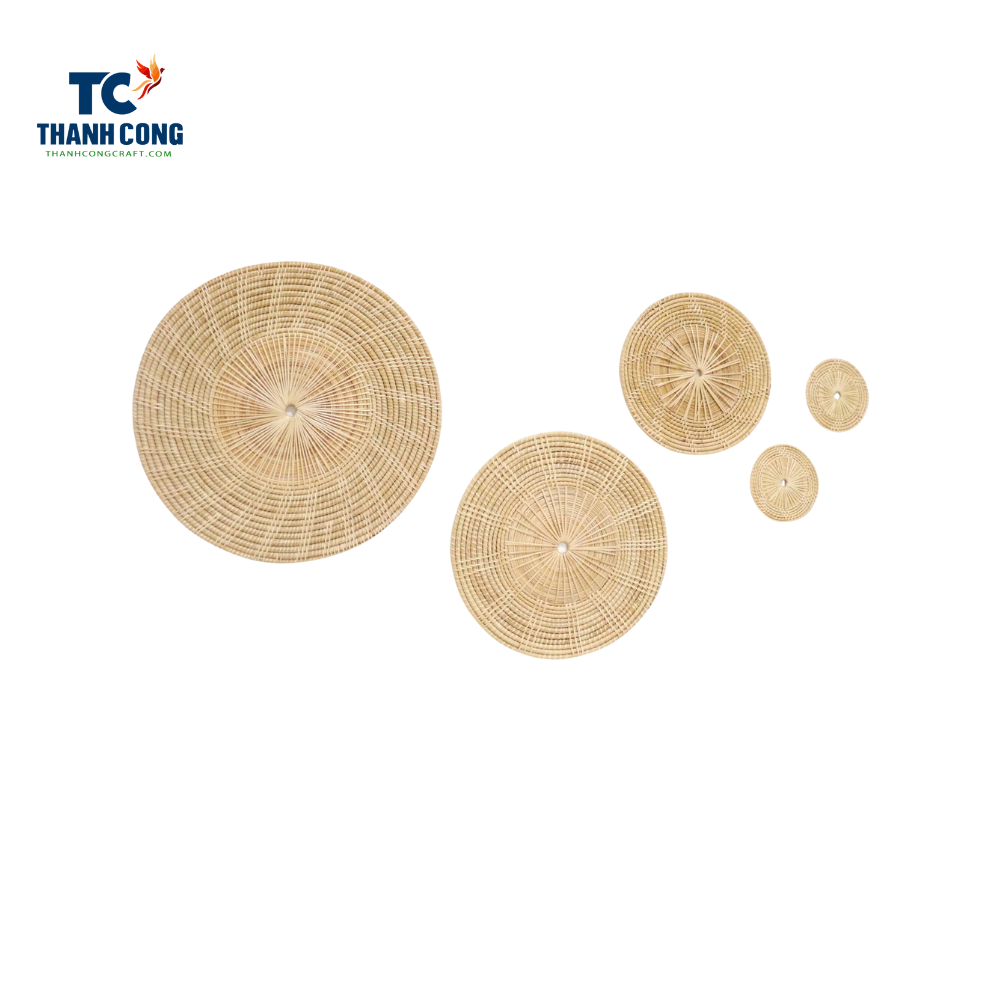

- Handicrafts: Coconut covering is often used to produce handicrafts, including baskets, bowls, and mats. The fibres of the shell are woven into intricate patterns, giving the finished product a unique and attractive appearance. (Check out our Coconut Bowls)

- Mulch: The fibres from coconut covering, known as coir, are an excellent material for garden mulch. The coir retains water well and can improve soil aeration and drainage.

- Fuel and charcoal: The rigid and sturdy nature of coconut covering makes it an ideal material for producing fuel and charcoal. The covering is an excellent biomass energy source and can be used in heating and cooking.

- Soil stabilization: Coir fibres are often used to stabilize soil in construction sites and other areas where erosion is a concern. The fibres help to prevent soil erosion by providing a protective covering and improving soil stability.

- Animal bedding: Coconut covering can be used as bedding for animals, such as horses, rabbits, and poultry. The fibres provide excellent insulation and absorb moisture, making them a comfortable and hygienic bedding material.

In summary, coconut covering has various applications, ranging from producing handicrafts to serving as a growing medium for horticulture. Its unique properties, such as its hardness and water retention capacity, make it an excellent material for various industrial and agricultural applications.

Processing of coconut covering

Coconut covering, the outer layer of the coconut fruit, undergoes a series of processing steps to make it suitable for various applications. Here are some of the typical steps involved in processing coconut covering:

- Harvesting: Coconut fruits are harvested when mature and the outer covering has turned brown. The covering is removed from the fruit using a sharp knife or machete.

- Dehusking: The hard, fibrous outer layer of the covering, known as the mesocarp, is removed using specialized equipment, such as a coconut dehusking machine.

- Decorticating: The fibrous layer, known as coir, is then separated from the more rigid shell layer using a decorticator. The coir is then cleaned and sorted according to fibre length and quality.

- Washing and drying: The coir fibres are washed thoroughly with water to remove any impurities and excess dust. They are then dried under the sun or using a mechanical dryer until they reach the desired moisture content.

- Processing for different applications: The coir fibres are then processed further depending on their intended application. For example, they may be used to make mats, baskets, or garden mulch or compressed to form fuel or charcoal.

- Packaging and distribution: The finished products are then packaged and distributed to various customers or markets locally or internationally.

The processing involves several steps, from harvesting and dehusking to washing, drying, and further processing. Each step is crucial in producing high-quality coir fibres that meet specific customer needs and applications.

Sustainability and environmental impact

Sustainable production methods

Sustainable production methods for coconut covering involve reducing environmental impacts and promoting social and economic benefits for local communities. Here are some of the common sustainable production methods used in the coconut industry:

- Organic farming: Coconut trees are grown without synthetic fertilizers or pesticides, reducing environmental pollution and promoting biodiversity.

- Efficient water use: Coconut trees are watered efficiently, reducing water waste and conserving this precious resource.

- Recycling and waste reduction: Coconut covering waste is reduced by recycling and reusing it to make products such as coir pith, a by-product of the coir fibre extraction process.

- Community development: Sustainable production methods also promote social and economic benefits for local communities. This includes creating job opportunities, promoting fair wages and working conditions, and investing in community development projects.

- Energy efficiency: Sustainable production methods also promote energy-efficient technologies in the processing and production of coconut covering, reducing greenhouse gas emissions and minimizing the industry’s carbon footprint.

In summary, sustainable production methods for coconut covering focus on reducing environmental impacts and promoting social and economic benefits for local communities. By adopting sustainable practices, the coconut industry can promote long-term sustainability and resilience while meeting the growing demand for coconut products worldwide.

Environmental benefits of using coconut covering

Using coconut covering, the outer layer of the coconut fruit has several environmental benefits, including its biodegradability, renewability, and ability to sequester carbon. Here are some of the most notable benefits:

- Biodegradability: It is biodegradable, meaning it breaks down naturally and does not contribute to environmental pollution or waste.

- Renewable resource: Coconut trees are a renewable resource that can produce coconuts for several decades, making it a sustainable material choice.

- Carbon sequestration: Coconut trees absorb carbon dioxide from the atmosphere, helping mitigate climate change’s effects.

- Reduced need for synthetic materials: Using coconut husk products as the natural material reduces the need for synthetic materials often produced using fossil fuels and other non-renewable resources.

- Waste reduction: Using coconut waste for producing coir pith and other products reduces waste and promotes a circular economy.

- Erosion control: Using coir fibres for soil stabilization helps to prevent soil erosion, promoting soil health and preventing sediment runoff into waterways.

Check out our Coconut Products

Coconut covering is a versatile material with many applications, including erosion control, gardening, furniture making, etc. Future research and development have immense potential for exploring new applications, improving sustainable production methods, enhancing product quality, and reducing waste.

If you have further questions, don’t hesitate to send us an email at info@thanhcongcraft.com or leave us a message at WhatsApp: +84967485411.